The Five Horseshoes

Situation

The Five Horseshoes Inn (235 square metres) in the picturesque small village of Barholm in South Lincolnshire is a ‘‘hard to treat’’ property of the 18th century in a rural off gas area. It’s an atypical domestic oil fired building size and construction type whilst having the commercial advantages of having large parking and outdoor facilities. The property has solid uninsulated walls, a mix of solid and suspended timber floors, uninsulated ceilings, mostly single-glazed wooden doors and windows, and large open fireplaces causing high air leakage. The oil-fired boiler, about 25-30 years old, is set to mid-range at 60,000 BTUs (around 17.5 kW).

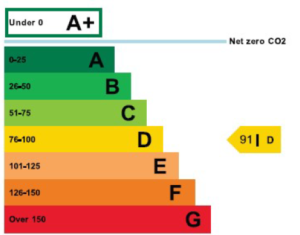

Energy efficiency rating for this property

Before boiler upgrading this property’s current energy rating was D.

Solution

The new heating solution involved replacing the existing oil fired Myson Velaire 50/70 boiler, which design and efficiency going back some 40 years., with fully modulating Sapphire liquid fuel boiler set for HVO, and a new oil Tank, supplied by EOGB Energy Products LTD and the Oil Tank Company.

The existing wet central heating and hot water system were retained. The 15 existing radiators were fitted with remote individual thermostatic flow and temperature sensing valves which provided individual radiator zone control functionality enabling app controlled separate time and temperature demand control over private residential and public areas of the property.

At the first stage, after upgrading the existing boiler to a Sapphire from EOGB, the energy rating of the 300-year-old property improved from the higher end of Band D to a mid-range Band C. In the second stage, the non-compliant oil storage tank was decommissioned and removed, and a new 2,500-litre Crown/HVO-branded integrally bunded steel oil storage tank, manufactured by J Seed & Co, was installed by the OFTEC Registered Oil Tank Company. This upgrade further improved the building’s energy efficiency rating from Band C to Band A.

The site is completely converted to 100% fossil Kerosene for its heating and hot water supply demands.

Benefits

Environmental Impact, Fuel Consumption & Calculated Carbon Savings

After HVO installation the fuel usage was monitored every month during next three years), emissions were calculated and compared to the previous six-year average kerosene fuel usage.

Switching to HVO, which is manufactured from used cooking oil, immediately reduced the pub’s annual carbon emissions by 88%.

Based on an annual consumption of 3000 litres of kerosene per annum estimated Carbon emissions in terms of CO2e were circa:

• 8.26 tonnes CO2e per annum.

HVO usage over the three-year term of the site gave an annual average fuel usage of 2817 litres per annum and calculated carbon emissions of:

• 0.986 tonnes CO2e per annum

(generic HVO)

• 0.702 tonnes CO2e per annum

(BRE analysis of Crown Oil HVO)

Carbon Neutrality

The property was took from a 90% target reduction in CO2e emissions to carbon neutrality by funding the planting of certificated carbon capture trees.

Matthew Thompson and Emma freeman, the landlords of the Five Horseshoes Inn, said:

‘‘It’s a fantastic bonus for us. We’re not eco-warriors, but you have to do your bit. When we were shown the figures for the carbon reduction, it made sense. If we continued to use our old heating for the next 25 years we would need to plant 200 trees to offset the carbon emissions. With the new system it’s just 13.’’

‘‘ The fuel combined with our new, energy-efficient boiler works so much better than before and we often forget that we’re no longer using kerosene. For pubs like us, this hassle-free low-cost solution to going green will be a real lifesaver.”

The Five Horseshoes Inn transition to HVO is part of a wider demonstration of nearly 150 other homes and businesses by trade associations OFTEC and UKIFDA. The project showcases the viability of the fuel as an affordable and realistic green heating solution for rural properties in support of the government’s target to achieve net-zero emissions in the UK by 2050.

Martin Cooke, Managing Director of EOGB, said:

‘‘ It’s great to prove the benefits of modulation and explore what exactly can be achieved in the real world when you combine best available technology with HVO produced from waste resources. Rural landlords and commercial business owners take note that it doesn’t need to be all electric to make the difference.’’

Technical

The Sapphire boiler is a modern fully modulating liquid fuel boiler, delivers the best energy efficiency and carbon emission reduction.

• Heat Output: 6-32 KW

• Total Electrical Consumption: 0.66 kWh

• Efficiency Rating: 98% (ErP A-rated)

• Water Content: 62 litres

• Fuel Type: Oil (compatible with standard heating oil and biofuel blends)

• Heat Exchanger: Stainless Steel (high durability and corrosion resistance)

• Burner Type: Low-NOx, modulating burner

• Control System: Integrated Smart. Controls with Wi-Fi connectivity, allowing remote monitoring and adjustment via a mobile app, plus option to use standard controls.

• Emissions: NOx emissions below 30 mg/kWh

• Dimensions: 425mm (W) x 860mm (H)

• Weight: 88 kg

• Warranty: 25 years on heat exchanger

• Maintenance: Low maintenance design with easy access for service and cleaning

• Additional Features:

OpenTherm thermostat

Multi-zone heating capability

Digital flame monitoring

Automatic fault diagnosis